Inquiry

Please do not hesitate to contact us for further information, quotations, etc.

At a glance they look similar in forming the strip material by moving the rolls freely, but the basic concept of FFX is quite different. Among the conventional common-use roll mills, all of them generally apply “Cage roll forming system” relying on so called “Air bending”as their basic technology, though there is a little difference in the grade of common-use roll and its forming process. It is well known that the power of this system is weak for strip deforming and that quite large deviation from its roll flower exists, and so-called rolling phenomena around strip material in operation is likely to occur. In the FFX mill, the basis of forming is emphasized in”the restricted forming by the contoured rolls”, and the upper and lower rolls at BD stands are regarded as the most vital. We believe that by starting quality forming right from the most important step of the roll-forming process at the BD top-bottom roll, out technology will be able to set the operators minds at ease.

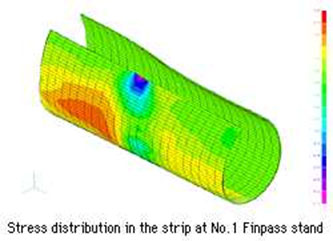

This is our unique forming technology with the original and patented FF rolls (Flexible Forming). Namely, this technology consists of (1)forming the strip with “the Involute curvatured rolls” with continuously changing radius of curvatures, and (2) the hardware and software to easily position the rolls for proper strip deformation. The most important technical elements are (1) “Proper Roll Caliber”and (2) “Precise Roll Positioning”in order to gain the required bending curvatures of the strip material, to which FEM (Finite Element Method) simulation technique greatly contributes. A tube mill, comprising of all of those elements is our FFX Mill which we can be called “intelligent mill” of the 21st century.

Roll forming of strip for pipe making is a very complicated process of tri-dimensional (as opposed to two-dimensional plate bending) deformation which is changing continuously. Considering the various dimensions and steel types, and the springback phenomenon or wrapping phenomenon around the roll during forming process, the skills of those people in the factory involved in such tube & pipe manufacturing must be really appreciated.

We have made a number of efforts to study such complicated deformation phenomena of the strip by utilizing “FEM” simulation technique. The issues which have been managed empirically till now due to no enough knowledge are now explained by FEM. Based on the knowledge gained by this “FEM”, “FFX Mill” has been completed, ensuring better quality forming of tube & pipe.

Approximately 15 minutes for small t/D sizes, and 30 minutes for larger t/D sizes.

Same philosophy is implemented with the NAKATA Rollbox, where round pipes are reshaped into shape pipes.

30″ Mill

Around 80 mill lines to date.