Inquiry

Please do not hesitate to contact us for further information, quotations, etc.

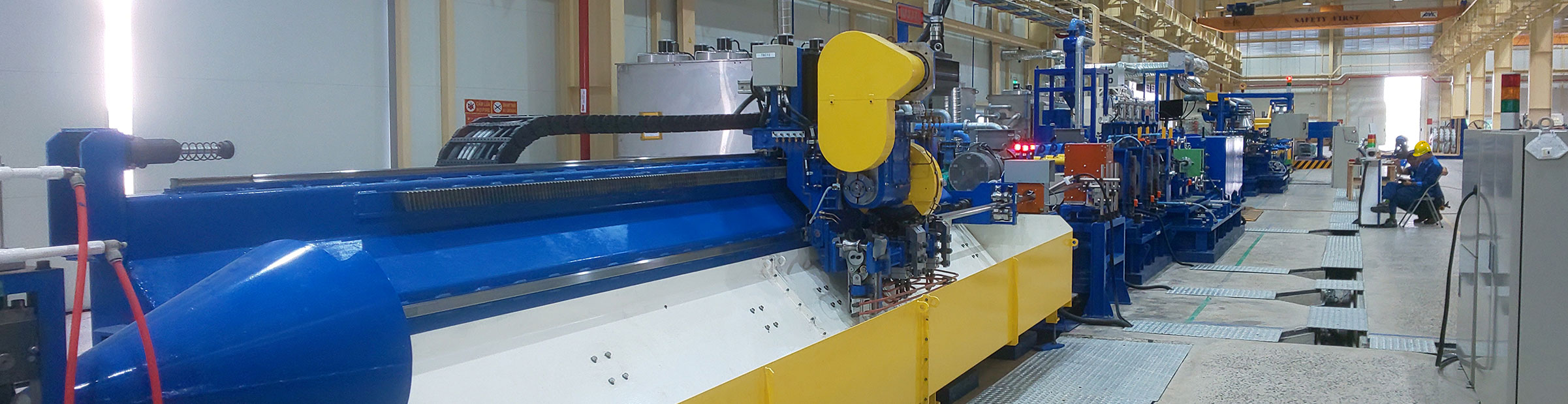

The cut off section plays an important role in line directly influencing its efficiency

We have unique rotary linear cut off machines equipped with high performance tip saw,

rotary swing cut off machine, and cold saw cut off machine.

This allows us to select the most suitable cut-off machine for your production line.

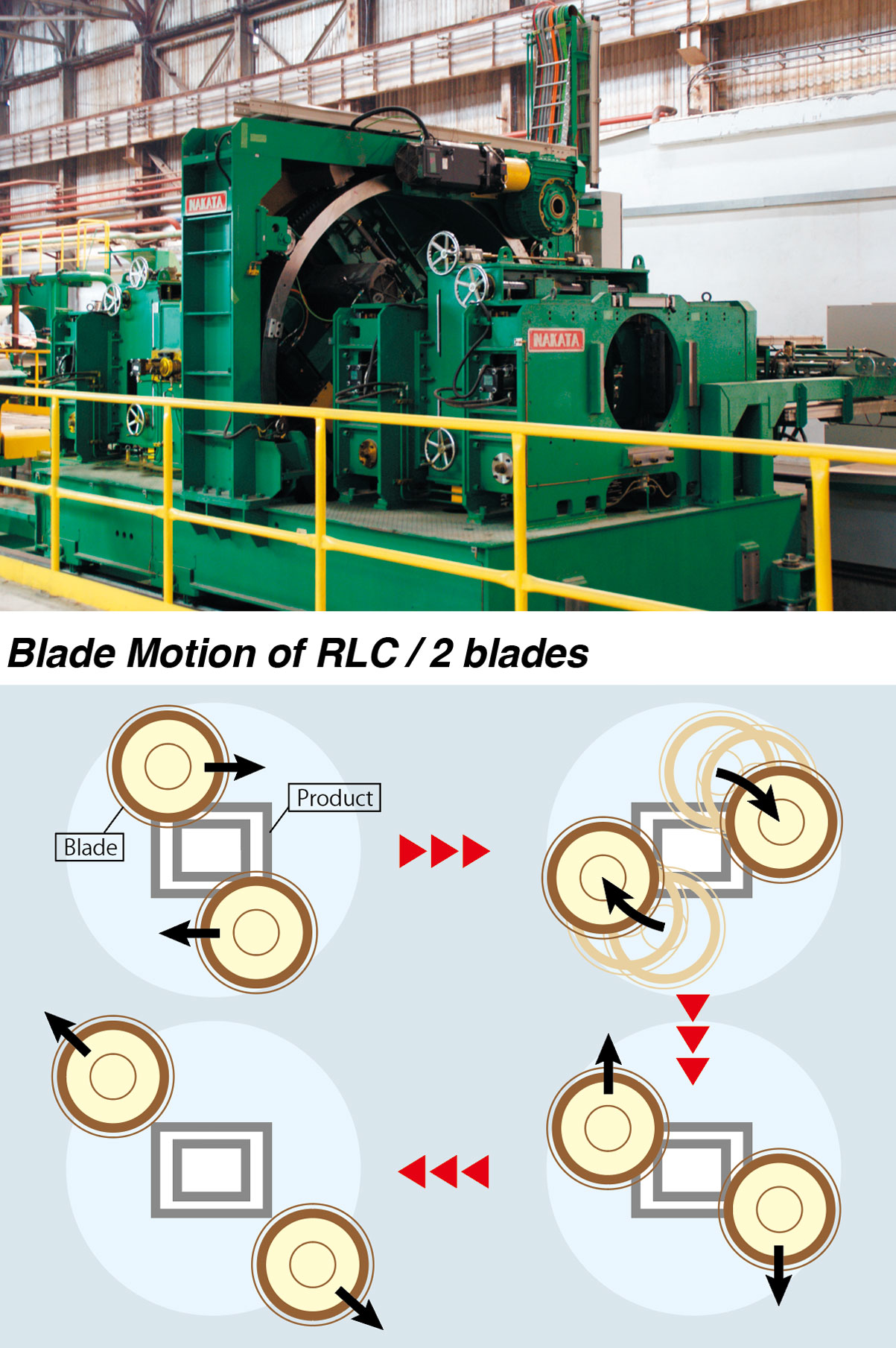

Specifications

| Cutting heads | 2 heads |

|---|---|

| Pipe size | 4~20 inches |

| Pipe shape | Round and shape pipes |

| Pipe material | carbon steel, alloy steel, high tensile steel, stainless steel |

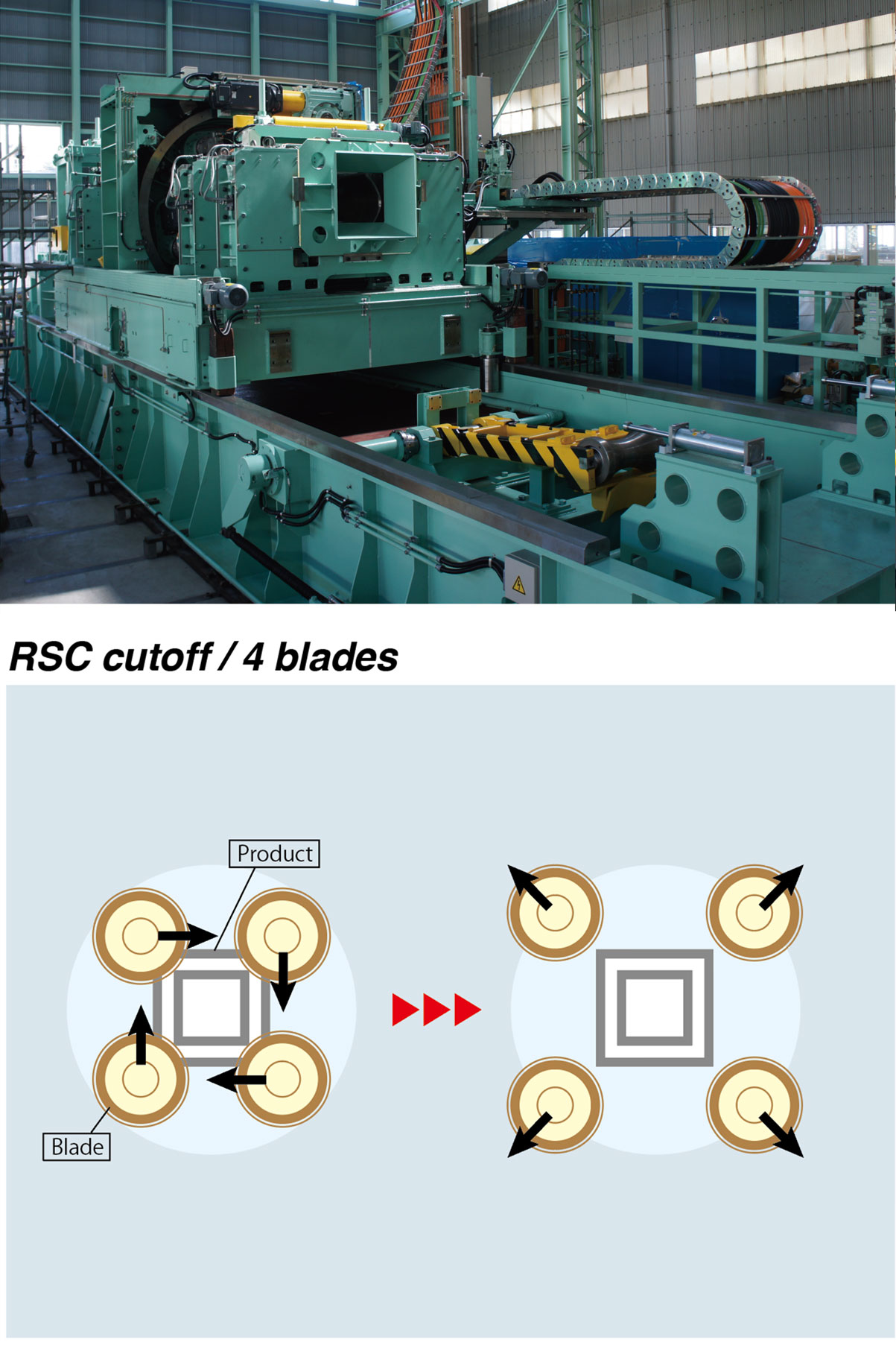

Specifications

| Cutting heads | 4 heads |

|---|---|

| Pipe size | 16~26 inches |

| Pipe shape | Round and shape pipes |

| Pipe material | carbon steel, alloy steel, high tensile steel, stainless steel |

Technical points

1.Supports all standards, steel types, and pipe shapes, a wide range of cutting conditions can be selected.

offering high speed light duty cutting to slow speed heavy duty cutting conditions.

2.Visual interface for selecting cutting conditions.

Ability to control machine while confirming the best cutting condition on the monitor.

3.Beautiful cut face and long lasting blades.

No need for off line reprocessing and edge burr trimming.

4.Design provides collecting chips and requires min maintenance

The world’s lightest running cutting head enables increased cuts per minute and higher travel speed, and improves productivity.

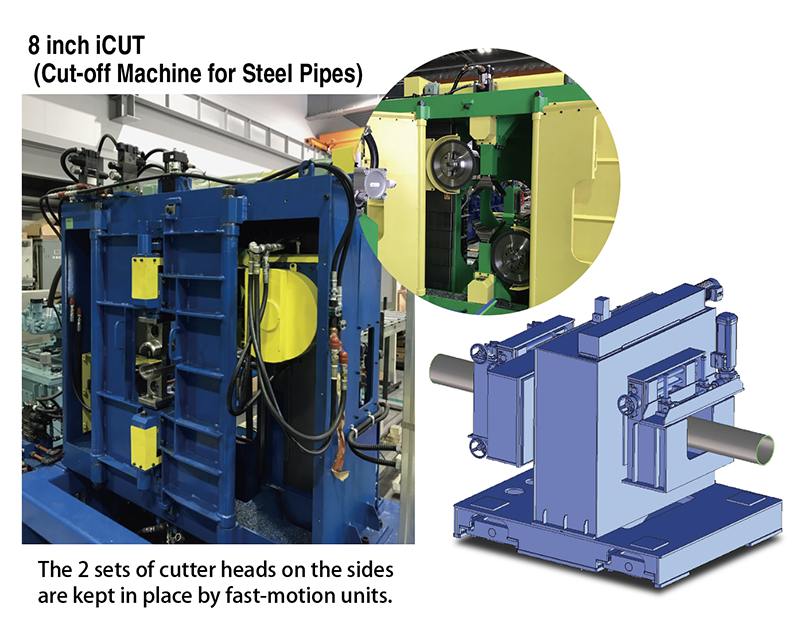

Latest model of cut-off machine for steel pipes “iCUT” Compared to conventional cut-off machines using circular saws, our machine boasts a lightweight but robust design that is both simple and compact. This enables users to produce high quality products at low costs.

Specifications

| Cutter Head | 2 sets |

|---|---|

| Product Size | OD 2 inch ~ OD 10 inch |

| Shape of products | Round Pipe |

| Steel Variety | Normal Steel, Alloy Steel |

Technical points

1.Clean cutting surface

Able to achieve clean surface with minimal off-set

2.Simple and compact design

Lightweight and stable structure thanks to robust blade feed mechanism with a highly accurate and highly rigid support mechanism.

3.Advanced software allowing easy operation

Cutting data will be calculated automatically once the product specification is input

4.Wide range of cutting options as well as long lifespan of cut-off blade

By appropriately selecting the depth of cut per blade at a relatively high cutting speed, we can ensure a wide range of cutting conditions and extend the life of the blade.

5.Easy chips removal

Chips are collected in the chip box placed at the bottom of the machine, making chips removal and machine clean-up easy.

6.Shorter time required for blade and clamp change

The open modular design on this machine enables easier and faster replacement of tools

Specifications

| Cutter Head | 1 sets |

|---|---|

| Product Size | Below 5 inch |

| Shape of products | Round and Square Pipes |

| Steel Variety | Normal steel, allow steel, High tensile strength, stainless steel, AC servomotor control system |