Inquiry

Please do not hesitate to contact us for further information, quotations, etc.

The entry section continuously feeds the strip into the mill.

NAKATA will offer the most suitable accumulator for your production line.

Horizontal Accumulator

Vertical Accumulator

Selection criteria

Vertical and horizontal types are available for selection, depending on the size of pipes, steel grade and the factory layout.

Functions

1. Stable coil strip feed that synchronizes with production speed as it changes.

2. Prevents scratches on coil surface

The helical edge miller developed by Nakata applies an epoch‐making cutting method, providing high speed and heavy duty cutting. To date, our helical edge millers are working in many mill lines across the world. Replacing old side trimmers and traditional edge millers, NAKATA’s helical edge miller proves competitive in its ability to vastly improve material yield and welding quality with its high level of automation.

Helical edge miller 8inch

Helical edge miller 20inch

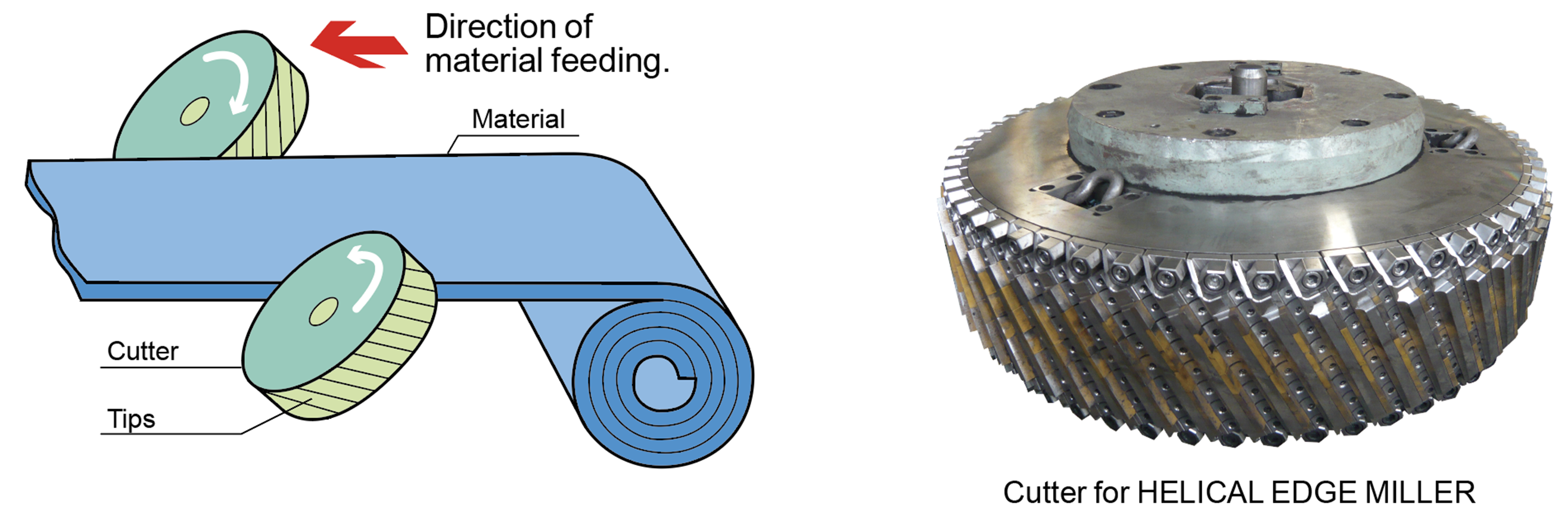

①Cutting principle

Usually, a large diameter cutter is required to improve cutting ability. By inclining the cutter axis at a specific angle in the material feeding direction, Helical edge millers can achieve important ellipse effect, slide cutting effect and moving effect of cutting point on cutting tip. This results in a higher cutting performance even with small diameter cutters.

②Features

1.Excellent cutting performance

2.Long lifetime of cutting tools

3.High shock absorption

4.Shorter cutter change time

5.Reduced damage to cutter

6.High material yield