Inquiry

Please do not hesitate to contact us for further information, quotations, etc.

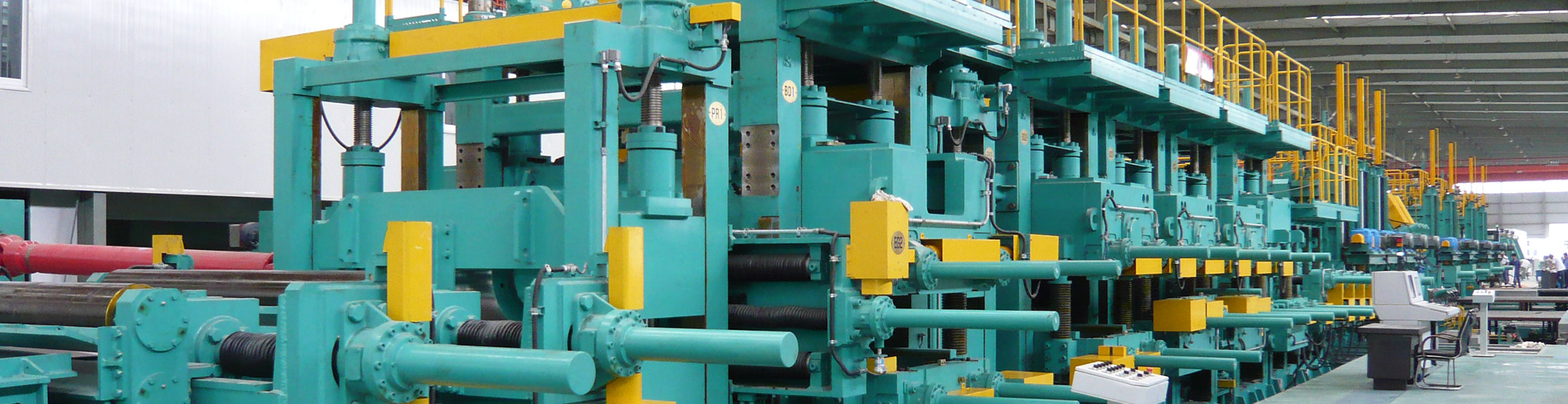

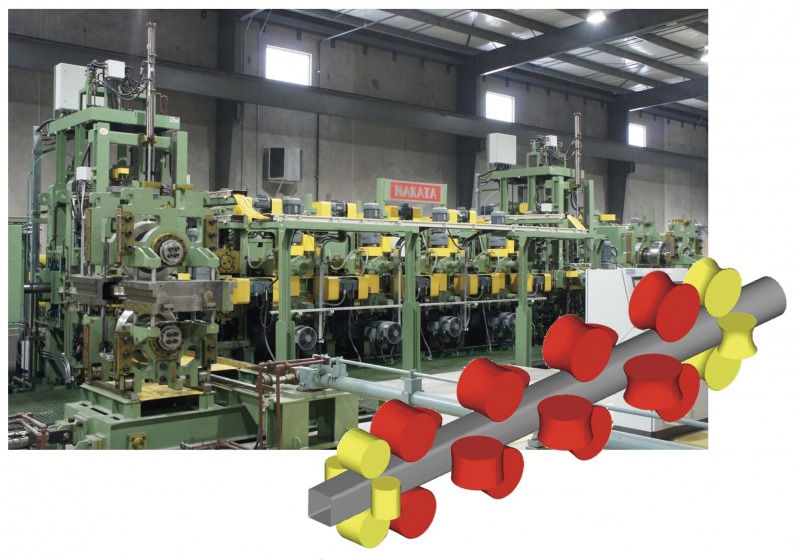

From breakdown to finpass and sizing, the mill section is compiled of equipment

consistently designed by FEM analysis, ensuring ideal forming with our proprietary

technologies for manufacturing the best tubes and pipes.

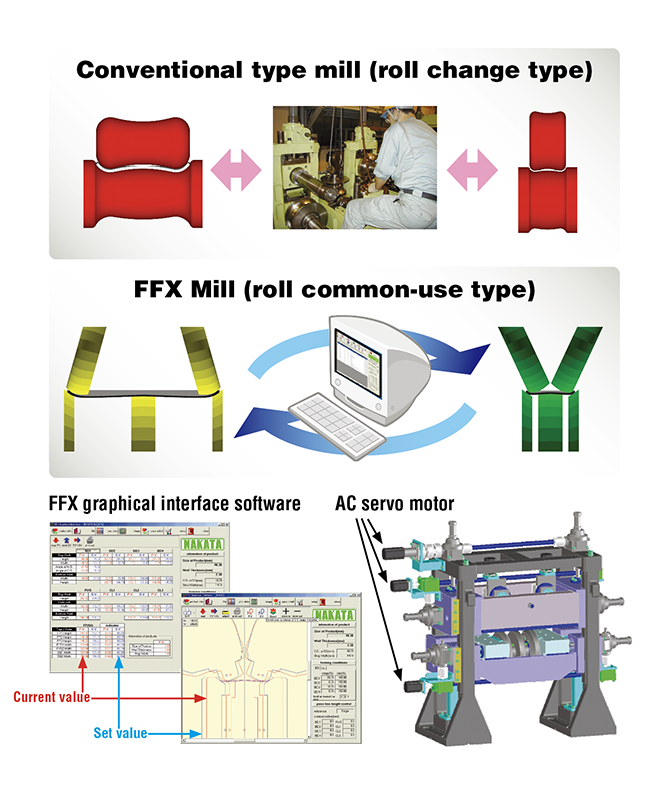

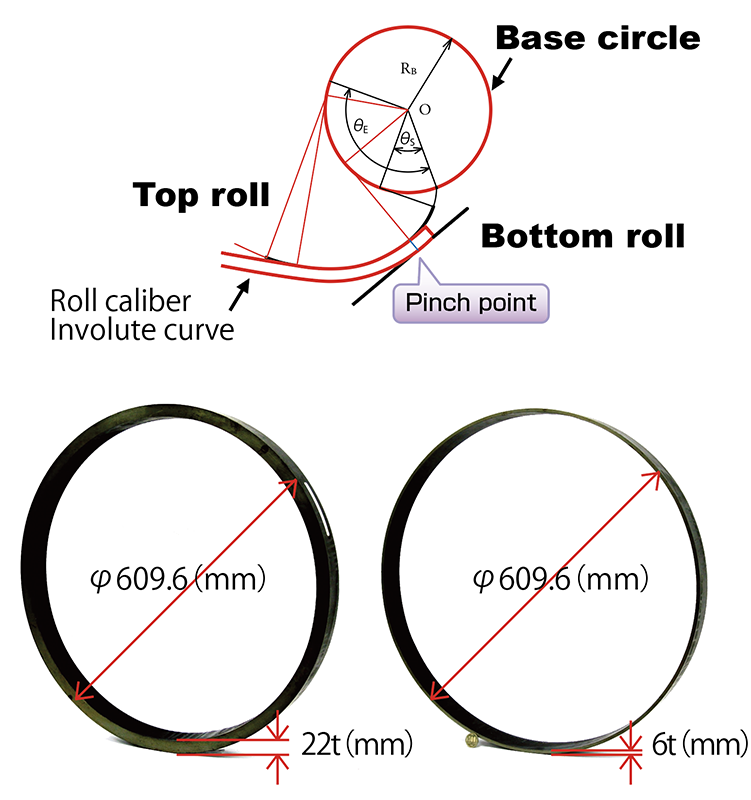

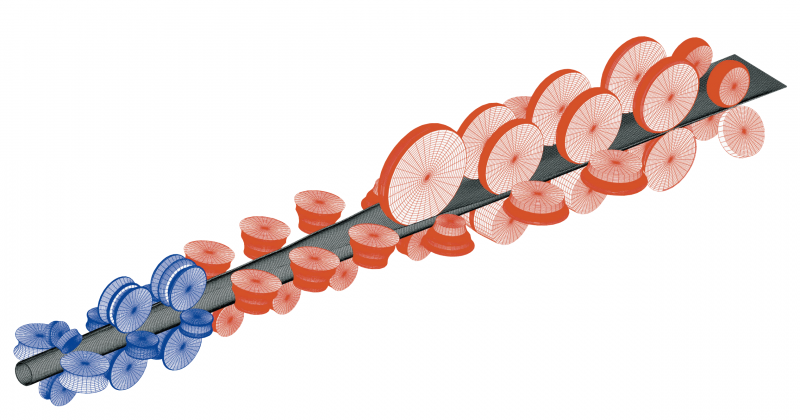

Developed with our cutting-edge technology, the most unique feature of the “FFX Mill” lies in its use of rotational common-use rolls with involute curved profiles. This allows the mill to cater to a wide variety of production conditions such as various product diameters, material thicknesses or steel grades. Not only does the FFX Mill incorporate common-use of breakdown rolls in production, it is also able to reproduce optimum roll forming conditions by NC control system to produce quality products with high ductility, high dimensional accuracy and perfect welding quality.

1.Possible to manufacture the pipes from large to small diameter (O.D. ratio 1:3) without roll change.

2.Highly accurate roll positioning by NC control.

1.Control of forming curvature by the rolls with involute curve profile.

2.Stable forming by embraced bending method.

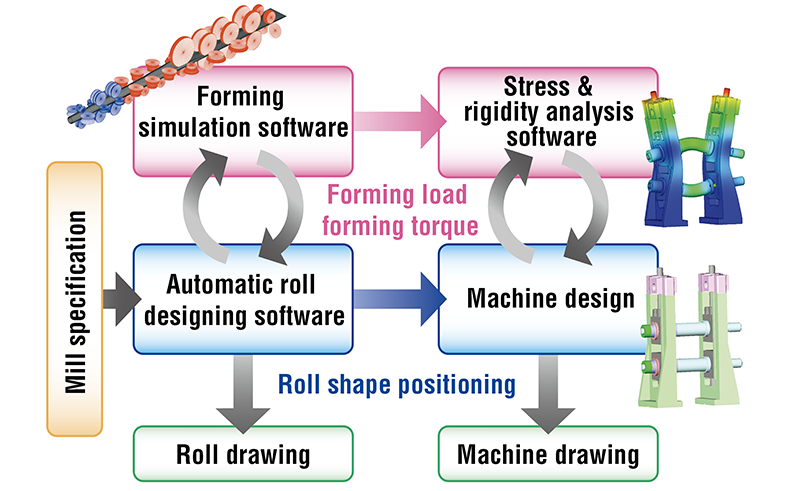

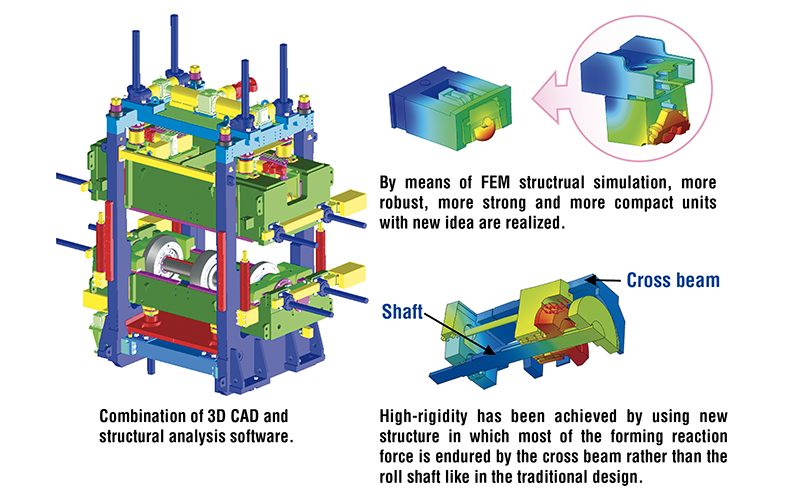

Optimized machine design with reasonable strength and rigidity based on the combination of metal forming analysis and mechanical structural analysis.

1.Unique proprietary analysis softwares that considers special characteristics of roll forming.

2.Parallel structure analysis simulation system for high speed and large capacity processing.

Compact and stable machine structure with high strength and high rigidity, designed combining the use of 3D CAD and structural analysis software.

1. Drastic reduction of roll change and adjustment works.

2. Improved product quality

(Welding quality, Dimensions and shape, Mechanical properties)

3. Efficiency

1. Forming rolls (quantity is reduced by half, as compared with conventional system)

2. Reduction of material waste (generated scrap is less by about 1/3, as compared with conventional system)

3. Energy efficiency (energy consumption is reduced by approximately 20%, as compared with conventional system)

4. Expansion of ERW pipe market

1. Able to work with hard-to-form materials, such as high strength steel

2. Entering new pipe markets.

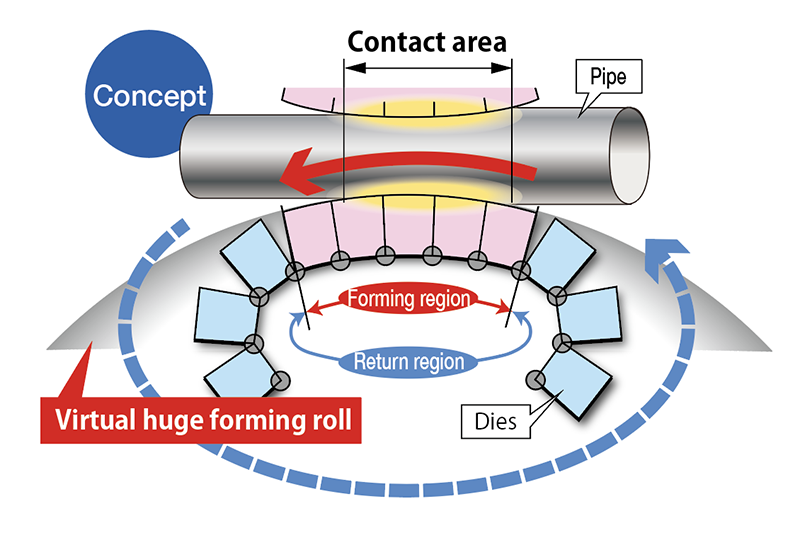

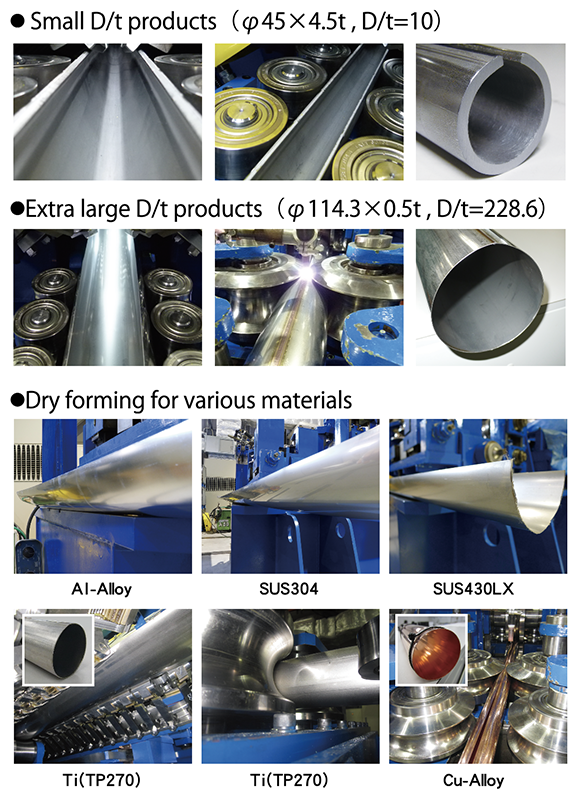

ODF makes use of multiple die blocks moving in the circumferential direction on an endless track, which are connected together to provide a tool surface with a very large curvature radius and work just like a huge roll. The new forming method eliminates the slippage problem between tool surfaces and metal strip and can cover a wide product range from large diameter pipes with super thin wall thickness to small diameter pipes with extra heavy gauge. This ODF method is compatible with any forming technology of a pipe mill.

Advantages of using huge diameter forming rolls:

1. Nearly two dimensional forming in cross section similar to press forming method.

2. Large contact area with material ⇒ Lower contact stress with less speed difference.

3. The main difficulty lies in producing such a huge forming roll with ideal deforming applications.

Only the forming pass of contact zone is necessary for achieving forming results equivalent to huge rolls.

As a result, huge rolls are replaced with die blocks!.

In the effective forming area the dies are seamlessly contacting each other to ensure a tool surface equivalent to that of a huge roll, whereas in the other areas of die row, dies are separated to return by the shortest path back to the forming area, moving constantly in an endless track.

ODF can solve various issues typical for roll forming.

Excellent forming of a wide range of products from thick wall/small diameter to thin wall/large diameter, work with complex materials that are hard to deform.

| No. | Product dimensions | Types of material |

|---|---|---|

| 01 | 45.0×0.4t | Cu alloy(C1220R-1/2H) |

| 02 | 45.0×3.2t | Carbon steel(SPHC) |

| 03 | 45.0×4.5t | Carbon steel(SPHC) |

| 04 | 63.5×0.6t | Austenitic stainless steel(SUS304) |

| 05 | 63.5×0.6t | Ferritic stainless steel(SUS430LX) |

| 06 | 63.5×1.0t | Mg alloy |

| 07 | 63.5×1.5t | Carbon steel(SPCC) |

| 08 | 63.5×1.6t | Al alloy(5052R-H32) |

| 09 | 63.5×3.2t | Carbon steel(SPHC) |

| 10 | 114.3×0.5t | Austenitic stainless steel(SUS304-2B) |

| 11 | 114.3×0.7t | Austenitic stainless steel(SUS304-2B) |

| 12 | 114.3×3.0t | Al alloy |

| 13 | 114.3×4.0t | Al alloy |

| 14 | 63.5×1.0t | Ti (TP270) |

| 15 | 114.3×1.0t | High tensile steel (Ys=900MPa) |

| 16 | 114.3×2.0t | High tensile steel (Ys=760MPa) |

| 17 | 114.3×3.2t | Carbon steel (SS400) |

| 18 | 114.3×6.0t | Carbon steel (SS400) |

| 19 | 45×1.0t | High tensile steel (Ys=900MPa) |

| 20 | 45×2.0t | High tensile steel (Ys=760MPa) |

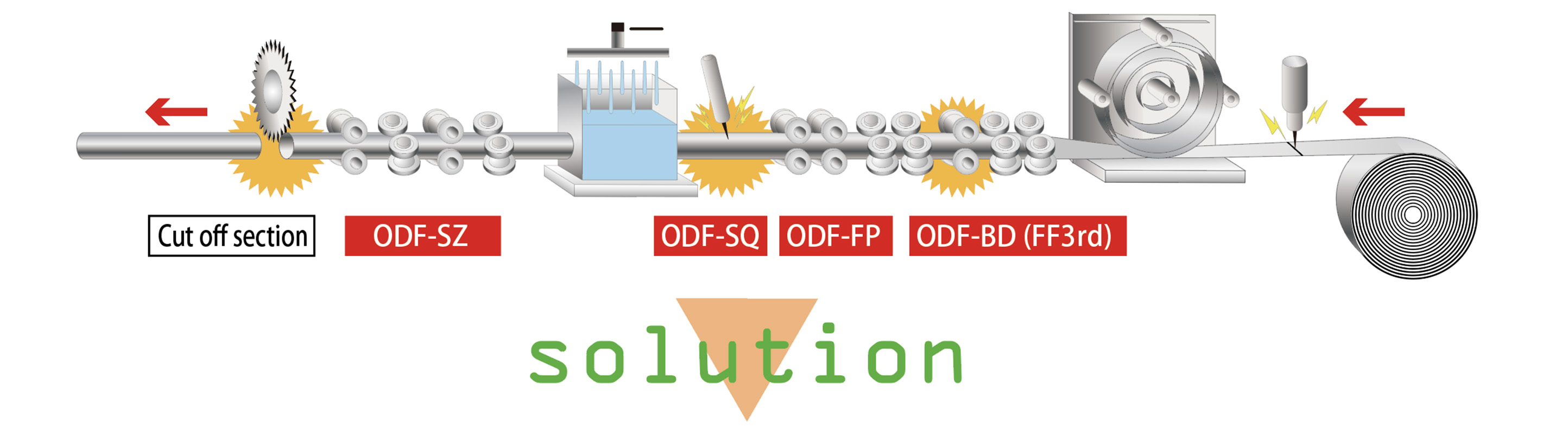

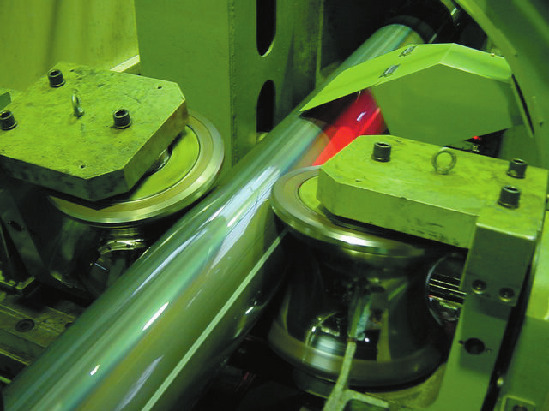

The fin-pass mill is a very important mill, located after FFX forming mill it creates suitable welding conditions. NAKATA’s system provides the best roll shapes and positions supported by FEM analysis. In addition, our proprietary roll change design, “Quick Change System” dramatically reduces workers’ workload and contributes to enhanced productivity.

Weld Bench is the most important equipment that determines the final product quality. It includes SQ stand, welder and inner and outer bead scarfer. We work both with induction type and contact type high frequency welding. NAKATA’s proprietary know-hows reduce spark and wear, which enable stable operation.

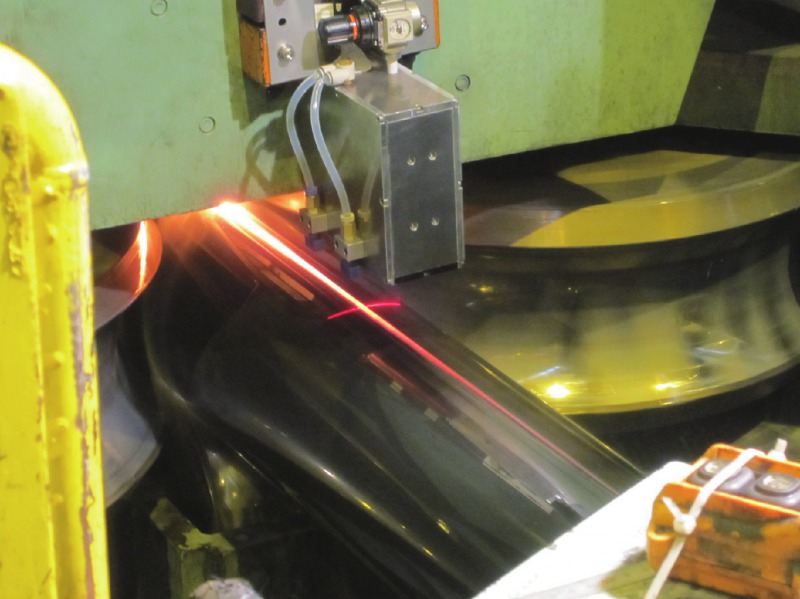

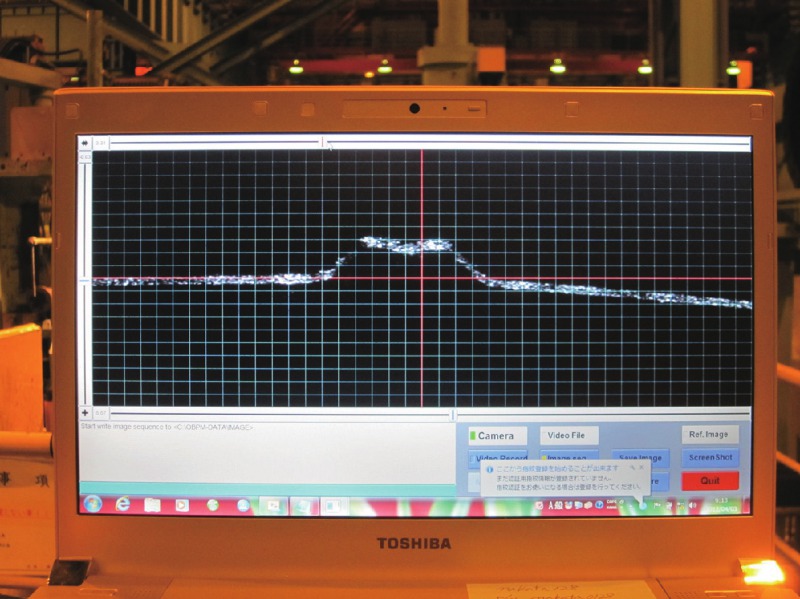

OD bead profile monitor (based on light slit method) is used to control welding quality. Two types of OD bead profile monitors can be provided. Single-ray type features a simple structure and is low in price. Double-ray type boasts the ability to observe the full bead profile including bead root portion.

Inner bead scarfer is used to remove the welding bead on the pipe ID surface. Based on the end-user’s requirements it can be cantilever type and have bead chopping function.

De-twist Stand is an equipment that controls the position of weld seam by twisting formed pipe. Our caliber design allows common-use rolls within a certain design range. We can also offer automatic adjustment system equipped with seam tracking.

Sizing stands are the key to assuring the dimensional accuracy of the final product. NAKATA’s designs provides both enough strength and high rigidity for stands and optimal roll profiles. Normally, the equipmentdesign is the same as that of the FP mill, and it is equipped with the same “Quick Change System”.

The turks head work in conjunction with the sizing mill to ensure pipe straightness.

Square / Rectangular pipe forming mill (Rollbox) with common-use rolls

Enjoy vastly enhanced profit margins owing to improved yield rate and productivity.

Swift investment returns (Min. 2 years) are ensured just by reduced costs of raw material!

1. Suppressed thickness at the corner area result in coil width reduction by up to 3%.

2. Up to 90% reduction in initial financial investment for rolls and running costs.

1. Up to 80% reduction in time required for roll change.

2. Suitable for small lot production of many sizes.

3. Quick setting for producing new sizes.

4. Optimized forming process can be selected depending on product size, wall-thickness and strength.